This is a little bit of research I did last semester, as I’m continuing it my investigations on this site I thought I’d move it over :)

Packaging is used in just about every aspect of our lives, you can’t really get away from it, even if you try!

It’s used to protect products in transport, keep food fresh, entice us to purchase, to provide warnings and to relay legal and safety information. Any product you design that will be available to the public will need to be packaged so what are the materials involved? What rules do you have to follow?

Materials

Paper and Board

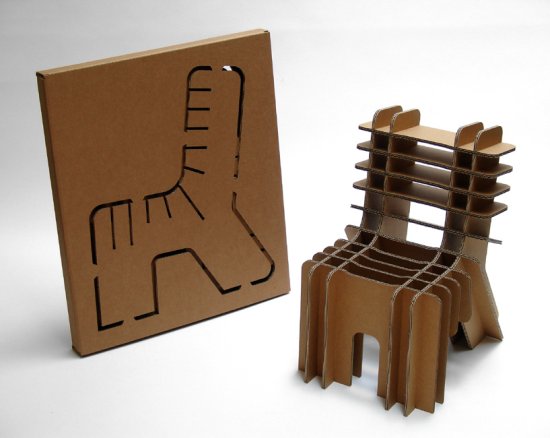

Paper and card are, next to plastics, the most used packaging material. It’s easy to cut, colour, print on, fold and form and it can be processed in hundreds of ways. One form is corrugated cardboard, a vary strong, light weigh material that you can see almost every day. Paper and board are cheap, light weight and versatile materials that can be easily recycled.

Glass

Glass is used for a lot of food and medicinal packaging as it is incredibly chemically inert. Nothing much can react with glass at room temperature. It’s clear so the product can be seen, amber glass as shown above has the amazing ability to filter out UV light! It is resistant to compression, internal pressure and heat and is low cost to produce and made of readily available raw materials. The down sides are it is very fragile and can be very heavy depending on the design of the container. Glass is also highly recyclable.

Metal

The main metals used in everyday packaging are steel and aluminium. To prevent the metal reacting with the product in side they have to be coated with an organic lacquer. You wouldn’t want to drink a can of Coke that had started to corrode the inside of the can!! Metals are strong and can be made into just about anything, cans, tins, tubes, crisp packets etc. The main disadvantage is weight and transport space, some supermarkets have started to replace tins with rectangular tetra packs as the pallet weight is reduced and you can fit more pallets into the same space.

Plastics

Plastic is cheap, light and can me made into just about any shape you can think of. Plastics can be broken down into two main areas, thermosetting and thermoplastics. Thermosetting plastics can only be formed once, if you tried to melt them again they would just burn! Thermoplastics can be formed over and over again just be re-heating them. The reason for the difference is in the nature of their chemical bonds, thermosetting plastics have strong bonds between the molecule strands, the ones in a thermoplastic are much weaker allowing them to break when heated so the molecules can flow past one another.

Rules and Regulations

There are different rules and regulations for packaging in different markets. The rules that affect the cosmetics industry will be different from those governing the drinks industry for example.

The Portman Code: This is a rule governing the packaging for alcoholic drinks. A companies packaging cannot encourage consumers to drink excessively or to emphasise the drink’s alcohol content. They are also not aloud to associate their product with drugs, violence or sexual success.

Braille: Since 2005 it has been mandatory for pharmasutical packaging to have it’s products name and strength printed on the packaging in braille.

Food Lableing: Any food sold must adhere to the food labelling regulations. Any product has to have an accurate description, it’s ingredients, place of origin and sell by date printed on it’s container. You’ve probable see the traffic light system a lot of the big supermarkets have adopted to make the nutritional content of their products clear, this has been done with the guidance of the Food Standards Agency.